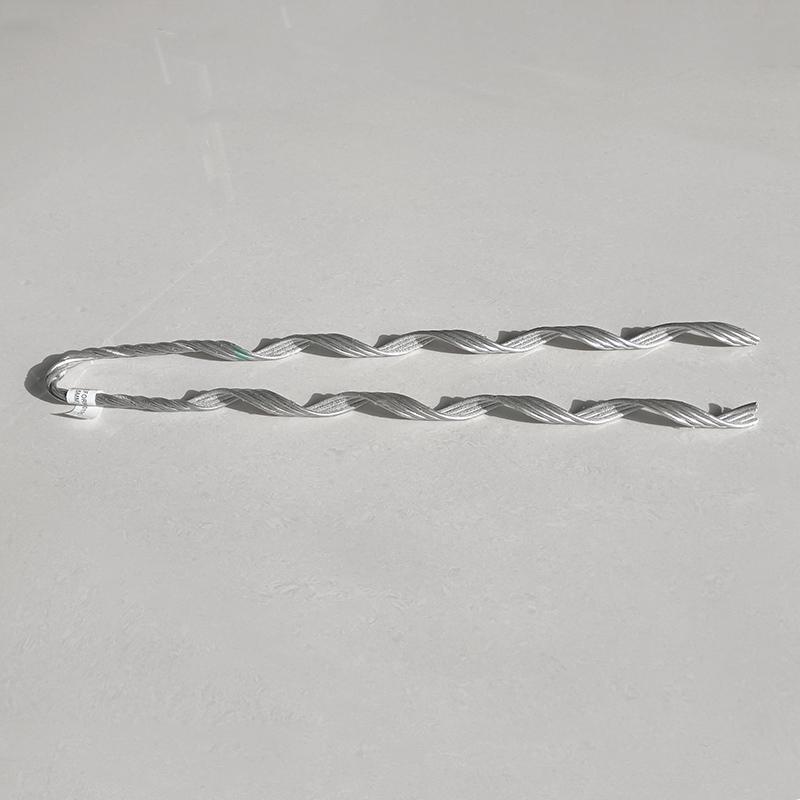

Wire tension clamp for steel core aluminum stranded wire1. The wire clip has good corrosion resistance; the material is exactly the same as the wire, ensuring that the wire clip has a strong ability to resist electrochemical corrosion. 2. The wire clamp adopts a spiral design, which improves the seismic resistance of the wire, uniform stress distribution, does not damage the wire, and prolongs the service life of the wire. Product technical specification sheet: Sn Model No.

Contacta ahora

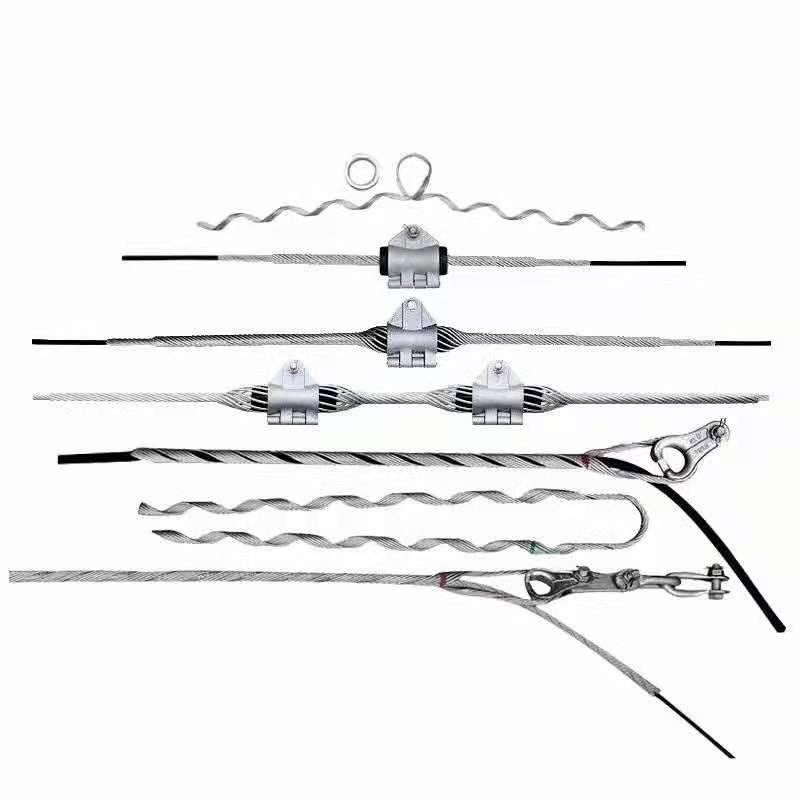

The structure of the preformed armor rod and the short protective rod is simple. A set of pre-twisted wires form an empty tube, which generates a gripping force when wrapping the wire, thereby protecting the wire. The pre-twisted wire protection line is used for vibration protection and has been included in the hardware products.

Contacta ahora

The S shape drop cable clamp is made of steel wire and ABS plastic clamp body, one head with a round steel wire, used to bind the self-supporting drop cable suspension wire, and hang the optical cable on the supporting device.Dimension:136×19.5×15mm(L×W×H).Instruction: Wrap the 2-5mm optical brazing wire in the cylindrical groove of the S part, and fix the optical brazing wire connecting rod.Installation image:Drawing:

Contacta ahora

1. The preformed guy grip is used for the installation of ACSR conductors. The product is with much more reliability and economy compared with the bolt-type & hydraulic strain clamps. 2. The structure of the preformed guy grip is simple. When installation, the tubular structure formed by the legs of the pre-twisted wire can be naturally wound on the conductor to produce a strong grip. The novel structure and unique design make the wire resistant to tension.

Contacta ahora

Wire tension clamp NL-50/8 for steel core aluminum stranded wire made of galvanized steel wire or alloy clad steel wire. 1. The preformed guy grip is used for the installation of ACSR conductors. The product is with much more reliability and economy compared with the bolt-type & hydraulic strain clamps. 2. The structure of the preformed guy grip is simple. When installation, the tubular structure formed by the legs of the pre-twisted wire can be naturally wound on the conductor to produce a strong grip.

Contacta ahora

The preformed top tie are all designed in a spiral structure and consist of two aluminum-clad steel wires. The central part of the power distribution cable is formed in the factory, and its shape can be matched with various insulators and wires.

Contacta ahora

1.The preformed guy grip is used for the installation of ACSR conductors. The product is with much more reliability and economy compared with the bolt-type & hydraulic strain clamps.2. The structure of the preformed guy grip is simple. When installation, the tubular structure formed by the legs of the pre-twisted wire can be naturally wound on the conductor to produce a strong grip. The novel structure and unique design make the wire resistant to tension.

Contacta ahora

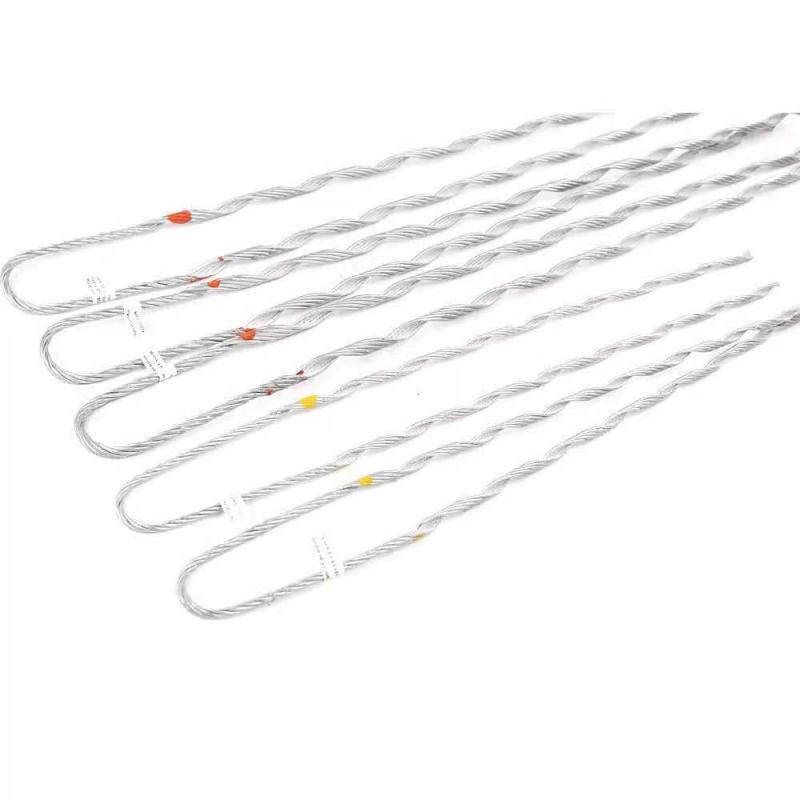

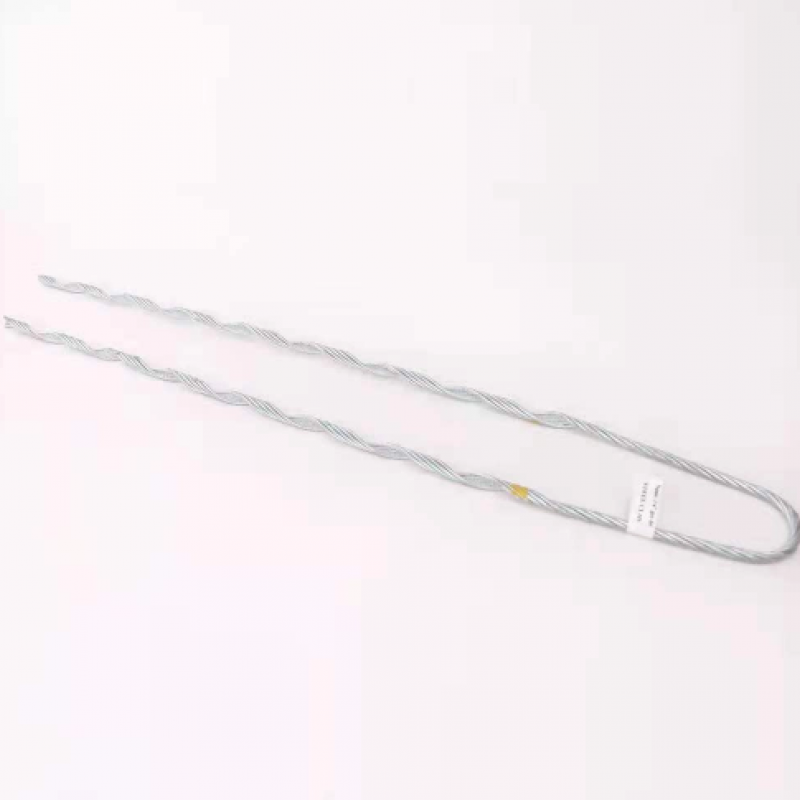

The preformed strain clamp is used to bear full tension on the bare conductors and overhead insulated conductors in the power transmission and distribution line, and connect the conductors to the strain tower, which can replace the conventional bolt-type strain clamp and compression type strain Clamps and wedge-shaped strain clamps.Structure composition and material description 1. Non-twisted ring: standard form, suitable for small diameter wires; Stranded ring: suitable for larger diameter wires 2. Color code: starting mark of installation 3. Label: Indicate the

Contacta ahora

The medium and high tension strain clamps are composed of a double-layer twisted wire structure. The tensile inner twisted wire is made of galvanized steel wire or aluminum-clad steel wire. The inner wall of the pre-twisted wire is stuck with a layer of fine emery to increase friction. The pre-twisted wire is preformed into four sub-bundles during processing to avoid installation errors and facilitate quick installation. The ends of the pre-twisted wires are bent radially outward to avoid squeezing and damaging the optical cable.

Contacta ahora

The structure of the preformed strain clamp is straightforward, and its pre-twisted cord legs are twisted to form an empty tube, and the rear part is a pre-formed twisted ring. the empty tube shaped via the legs of the pre-twisted twine can generate a robust grip while it's far wound at the wire, and the twisted loop is used to restore the insulator.

Contacta ahora

The S type cable clamp is used to bind the self-supporting leather cable suspension wire and hang the optical cable on the supporting device, be steadily strengthened and tightened. There are several colors can be chosen: gray, black, white.Instruction: Wrap the 2-5mm optical brazing wire in the cylindrical groove of the S part, and fix the optical brazing wire connecting rod.Packing: comes in plastic first then put in strong durable cardboard box with labels stick on the outer package. Installation image:

Contacta ahora

Product advantages: 1. There is a large contact area between the clamp and the pull wire, the stress distribution is even, there is no stress concentration point, and the achievable grip strength is not less than 95% of the stranded wire Calculate the breaking force. 2. The dead end preformed guy grip is made of the same material as the pull wire, which has good corrosion resistance. 3. The dead end preformed guy grip is simple to install, without any special tools, and can be done independently by one person.

Contacta ahora

The preformed dead end is used to fix the cable clamp of the cable of the tower, the iron tower, and the microwave tower. It can replace the U-T clamp and the wedge clamp that are commonly used to fix the cable on the line tower. The unique design makes the tension-resistant structure of the cable simple and reliable. After installation, the empty tube formed by the twisting of the two legs of the pre-twisted wire of the wire clip can be wound on the cable to produce a strong grip. The twisted ring is used to fix the ground anchor. Or on the tower pole.

Contacta ahora

Preformed inner protection line rods:The material is aluminum-clad steel wire, which is the same material as all the aluminum-clad steel wires of OPPC cable. The inner wall of the protector rods is glued with a layer of gold steel sand through a high-strength polymer water-soluble environmentally friendly adhesive to increase the friction with the optical cable. The rods is preformed into four sub-bundles during production, which is convenient for quick installation.

Contacta ahora

The power distribution top tie can be used to fix bare or insulated wires in the top grooves of pin insulators and post insulators of the power distribution system.

Contacta ahora

Features 1. There is a large contact area between the clamp and the wire, the stress distribution is even, there is no stress concentration point, and the achievable grip strength is not less than 95% of the stranded wire to calculate the breaking force.2. The wire clamp is made of the same material as the wire.3. The wire clamp is simple to install, does not require any complicated tools, and can be completed by one person.

Contacta ahora

The stainless steel buckle with tooth-shaped serrations and a certain arc on the back, which Bundle cables and signs can provide the greatest bundling strength. Features:-Buckles with rounded edges-With a toothed cavity for better grip of the steel tape-Flat body for fastening to the steel tape-With fins for maximum tension and fixed and secure grip of the steel tape-The buckle is for ¾-inch steel strapping tape.Packaging:The buckles packaging in plastic bags of 100 units and these in turn in cardboard boxes adequately protected against damage or humidity, with the requested customer info

Contacta ahora

The S drop cable clamp is made of stainless steel rope and flame-retardant ABS plastic body, one head with a round steel wire, used to bind the self-supporting drop cable suspension wire, and hang the optical cable on the supporting device.Dimension:135×23.5×17.5mm(L×W×H).Instruction: Wrap the 2-6mm optical brazing wire in the cylindrical groove of the S part, and fix the optical brazing wire connecting rod.Packing: plastic bag first then come in a resistant biodegradable cardboard box with the customer information in the visible part of the box. Installation image:

Contacta ahora

ADSS optical cable suspension clamps are used for the suspension and support of optical cables on straight poles.

Contacta ahora

1. The twisting direction of the steel stranded wire and the matching preformed guy grip needs to be the same, and the tensile strength of the galvanized steel wire is 1370N/mm2-1470N/mm2. 2. The white corundum used to increase the friction between the pre-twisted wire and the surface should meet the requirements of GB/T 2479.3. The surface of the preformed guy grip should be smooth and free of defects such as cracks, folds and scars.4. The size and tolerance of the pre-twisted wire The size of the pre-twisted wire should meet the requirements of the design d

Contacta ahora

Fiber to the home FTTH accessories, S-type fixing cable clamp are composed of stainless steel wire and flame-retardant ABS plastic parts. It is used to bind the self-supporting drop-in optical cable suspension wire and hang the optical cable on the supporting device.The S type cable clamp is used to bind the self-supporting leather cable suspension wire and hang the optical cable on the supporting device, be steadily strengthened and tightened. There are several colors can be chosen: gray, black, white.Instruction: Wrap the 2-5mm optical brazing wire in the cylindrical groove of

Contacta ahora

Square flat washer with 17.5mm diameter hole for 5/8" diameter bolt. Galvanized per ASTM A-153.Features:1. Material: steel2. Finish: galvanized3. Usage: for 5/8” bolts. Technical specification:

Contacta ahora

ADSS spiral helical dead end consists of an anchor shackle, thimble clevis and preformed guy grip of suitable length, which used for supporting ADSS fiber optic cable in tension at cable sections, acute turnings or at the terminal pole. -Design for quick and easy installation-Minimizing time consuming civil works -Provide a future proof aerial network-Temperature: -10°C up to +70°CSn Model No. Suitable for ADSS cable range(mm) 300M spanANZ 030/0940 8.6-9.4ANZ 030/1010 9.5-10.1ANZ 030/1070 10.2-10.7ANZ 030/1140 10.8-11.4ANZ 030/1220 11.5-12.2ANZ

Contacta ahora

Preformed dead end, Clamp-wedge Anchor (stainless steel), 5.5*8.5+-0.2mm for Flat mini FTTH cable outdoor middle size. Our SS wedge anchor clamp with the advantages below:1.Reduce cable maintenance expenses, avoid frequent repairs, save operating costs, and users get a better experience. 2.The FTTH technology has been widely used, the construction speed is also very fast, and the technical risk is low. 3. It provides a stable and reliable guarantee for fiber to the home, and the efficiency of network usage is improved.Dimension: 210×15mmDrawing:Installation image:

Contacta ahora